Hydrogen Fuel Cell Control System for Energy Management – HEBCS-WTRE-HEBCS-WTT

Xi’an Famous Electric Co., Ltd.

Certifications

All products are EU and ISO certified

Sensor Model: HEBCS-WTRE-HEBCS-WTT

Technical Specifications

| Parameter | Specification |

|---|---|

| Temperature Monitoring | 4-channel temperature acquisition (-40–90℃) |

| Pressure Monitoring | 0–100MPa |

| Voltage Monitoring | 0–120V |

| Current Monitoring | 0–200A |

| Output | 5 relay outputs |

| PWM Output | 2 channels |

| Wireless Transmission Distance | 5000m (line-of-sight, unobstructed) |

| Power Supply | DC 24V (±10%) |

| Place of Origin | China |

| Category | Fiber Amplifier |

| Customization | Accept customization |

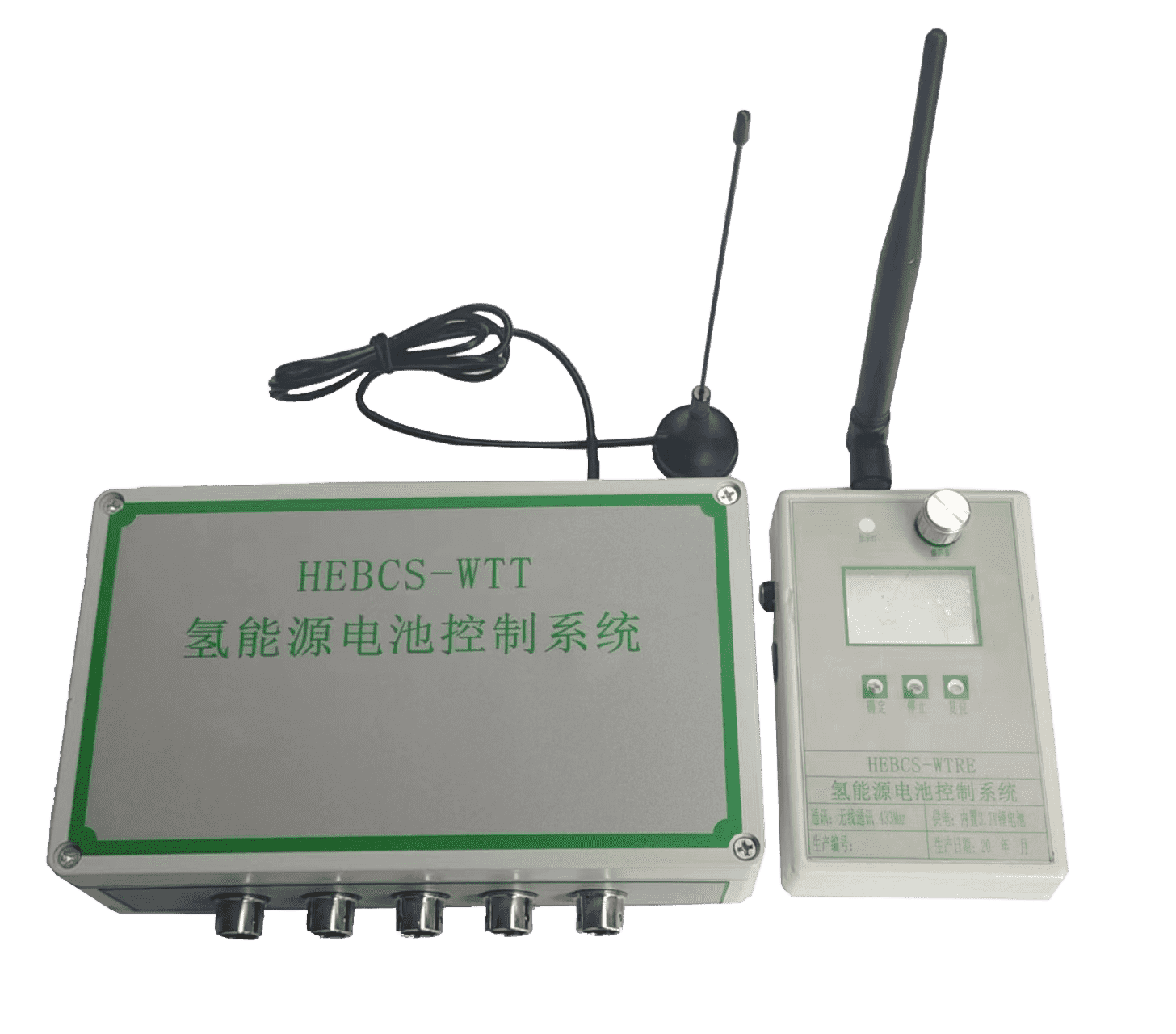

Pictures

Sensor Picture:HEBCS-WTRE-HEBCS-WTT

Key Features

✅ AI-Optimized Hydrogen Utilization

Real-time gas stoichiometry control with ±0.5% H₂ flow accuracy and 99.999% purity monitoring (ISO 14687-3 compliant).

✅ Multi-Stack Load Balancing

Dynamic 1-10MW parallel stack management with <5ms fault isolation (IEC 62282-2 certified).

✅ Extreme Environment Operation

-40°C cold start capability and 85°C thermal management via phase-change cooling (SAE J2601 compliant).

✅ Cybersecurity Protection

TLS 1.3 encrypted CAN FD communication with SIL3 functional safety (ISO 26262/21434).

✅ Smart Predictive Maintenance

Membrane hydration/degradation AI modeling with 95% failure pre-warning accuracy.

✅ Grid-Interactive Control

10ms response P2G/G2P mode switching for renewable energy buffering (IEC 61850-7-420).

Application Scenarios

🟡 Fuel Cell Vehicles

- Heavy-duty truck hybrid powertrain management

- Hydrogen train energy distribution

- Airport ground support equipment

🟡 Stationary Power Generation

- Microgrid peak shaving systems

- Data center backup power

- Telecom tower off-grid solutions

🟡 Industrial Decarbonization

- Steel mill hydrogen direct reduction

- Ammonia synthesis reactor control

- Port hydrogen refueling stations

🟡 Residential/Commercial

- Building combined heat & power

- Hospital emergency power

- Cold chain logistics refrigeration

🟡 Marine & Offshore

- Hydrogen-powered cargo ships

- Offshore platform auxiliary power

- Subsea equipment fuel cells

🟡 Extreme Environments

- Desert solar-hydrogen plants

- Arctic research stations

- High-altitude UAV propulsion

🟡 Energy Storage Systems

- Wind farm surplus energy conversion

- Seasonal hydrogen storage

- Nuclear plant load following

🟡 Hydrogen Infrastructure

- Electrolyzer array coordination

- Pipeline compressor control

- Liquid hydrogen pump stations

Your Concerns

Delivery

- ✅ Standard Products: 5-7 working days

- ✅ Customized Solutions : 15-20 working days

- ✅ Expedited Service: 3-day

Transportation

- Sea freight

- Air freight

- China-Europe express

Payment

- Western Union

- L/C at Sight

- PayPal

Quality

- 100% Pre-shipment Inspection

- Marine Insurance

- Anti-Static/Shock-Proof Packaging

Documents

Install Video

Description

The HEBCS-WTRE-HEBCS-WTT is a hydrogen fuel cell control system designed for efficient energy regulation and system monitoring in hydrogen-based power solutions. It supports real-time control, fault detection, and data communication, making it ideal for renewable energy, automotive, and industrial hydrogen energy applications.FAQ – Hydrogen Fuel Cell Control System, HEBCS-WTRE-HEBCS-WTT

✅ What is the HEBCS-WTRE-HEBCS-WTT hydrogen fuel cell control system?

The HEBCS-WTRE-HEBCS-WTT is a hydrogen fuel cell control system designed for efficient energy management, real-time monitoring, fault detection, and data communication in renewable energy, automotive, and industrial hydrogen applications.✅ What are the technical specifications of the HEBCS-WTRE-HEBCS-WTT system?

It includes 4-channel temperature monitoring (-40–90℃), pressure monitoring (0–100MPa), voltage monitoring (0–120V), current monitoring (0–200A), 5 relay outputs, 2 PWM outputs, and wireless transmission up to 5000m. The system operates on DC 24V (±10%) and supports customization.✅ What key features does the HEBCS-WTRE-HEBCS-WTT provide for hydrogen energy management?

Features include AI-optimized hydrogen utilization (±0.5% H₂ flow accuracy), multi-stack load balancing with <5ms fault isolation, extreme environment operation (-40°C to 85°C), cybersecurity protection with TLS 1.3 and SIL3 safety compliance, predictive maintenance with 95% pre-warning accuracy, and grid-interactive P2G/G2P control.✅ In which applications is the HEBCS-WTRE-HEBCS-WTT commonly used?

It is used in fuel cell vehicles, stationary power generation, industrial decarbonization, residential/commercial CHP, marine/offshore hydrogen systems, extreme environment operations, energy storage systems, and hydrogen infrastructure.✅ How does the HEBCS-WTRE-HEBCS-WTT ensure safety and reliability?

The system offers AI-based monitoring, SIL3 functional safety, encrypted CAN FD communication, extreme environment durability, and real-time fault isolation to guarantee reliable and safe hydrogen energy management.✅ Is the HEBCS-WTRE-HEBCS-WTT system certified?

Yes, it is CE and ISO9001 certified, ensuring compliance with European and international safety, quality, and performance standards.Contact & Support

Contact Our Engineers

📞 +86-029-86416613-5714 | +86 18092239472 | +86 18192259863

📧 fmssales3@xafms.com | estxs03@xaest.com

📍 Address:Xi 'an Gaoling District Ronghao Industrial City China V3-03